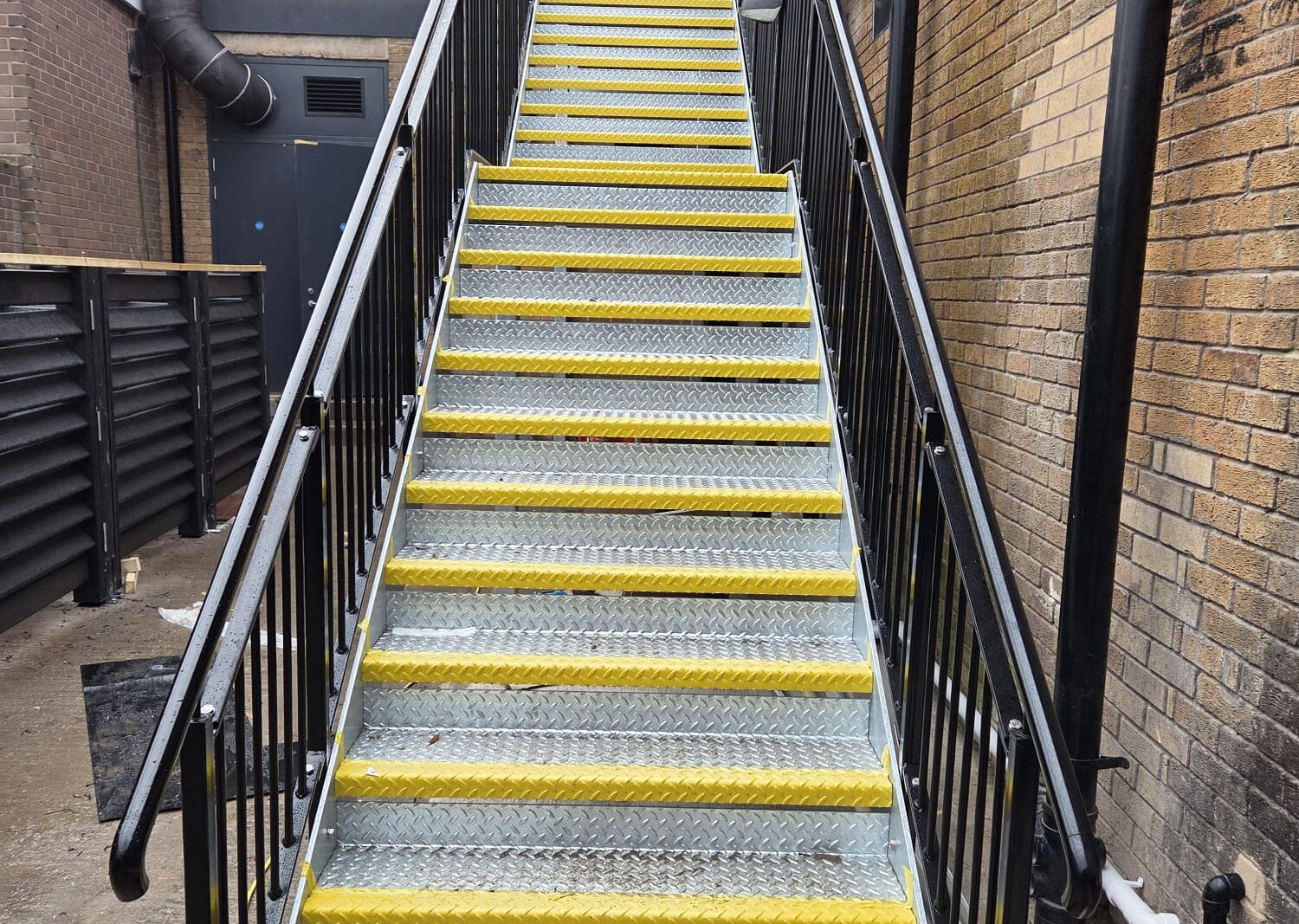

Fire Escape Staircase Installation

This fire escape staircase installation shows how a clean, robust external route can double as a compliant escape for apartments and commercial units. We organised transport via lorry-mounted crane for this installation of the main staircase, while the balustrade components were delivered to site by our vans. Everything was powder coated for long outdoor life and low upkeep. The system meets standards and passed inspection without fuss, providing our client with a neat, safe exit route for tennants which works in all weather.

- Correct rise, going, handrail heights for non-domestic use

- Anti-slip chequer plate treads with high-visibility nosings

- Powder-coated steel for corrosion resistance

- Solid infill plates near stairs by client request

Project photos

Walkway balustrade

Continuous top rails with vertical infills provide safe movement on the upper walkway. The balustrade aligns to the fire escape staircase installation enabling people can pass without snag points.

Solid infill plates

Custom steel plates near the staircase landing improve privacy and containment. Plates are fixed to the balustrade posts and finished to match the installation.

Anti-slip treads

Durable chequer plate treads suit external use and winter conditions.

Fire escape staircase installation specs

Every fire escape staircase we deliver follows core specs for compliance and usability:

- Stair geometry – Consistent rise and going across flights. Landings give safe resting points and turning space.

- Handrails – Continuous, easy to grip, returned to walls or finished to reduce clothing snag. Heights set for non-domestic routes.

- Guarding – Balustrade height and infill spacing meet UK guarding rules for places of work and common areas.

- Treads and nosings – Anti-slip chequer plate or gritted surfaces with clear nosings increase foot placement accuracy in rain.

- Structure – Steel sections sized for live load and dynamic movement on busy routes.

- Finishes – Galvanising or zinc-rich primer with powder coating for impact resistance and long life.

- Fixings and drainage – Closed ends and drip details limit water traps. Through-bolts and plates spread loads into sound structure.

This approach keeps your fire escape staircase installation simple to inspect and reliable when people need it.

Outdoor durability

External stairs live in wet, cold conditions. We specify coatings and details that protect steel for years. Powder coating reduces maintenance and keeps the staircase & balustrade looking tidy. Drainage gaps move water away from walking lines. Handrail joints are sealed to stop ingress at sleeves.

Full installation service

We handle design drawings, site measures, fabrication, transport, and installation. Modules are lifted, aligned, and fixed with minimal disruption to your programme. Our team coordinates with contractors so the installation goes in cleanly and passes checks first time.

On-site checklist

- Confirm fixing substrate is sound and level before lift.

- Check rise/going, handrail height, and guarding height with a tape at first fit.

- Tighten all primary bolts, then secondary fixings.

- Seal end caps and joints after final alignment.

- Clean down

Call 01746 763477 • Email [email protected]

FAQs

Do you handle design and installation?

Can this be adapted for small sites?

How long will it last?

What are typical lead times?

Standards and resources

For design intent and checks, review the UK guidance. Approved Document B explains escape routes and protection. See the official resource Approved Document B: Fire safety. This external source helps you verify a fire escape staircase installation against high-level requirements.

Send your sizes and photos. We’ll return a clear, itemised quote.